1 PICKUP

One of our company trucks with spill containment will pick your transformers up. Our fleet is highly trained and experienced at hauling transformers.

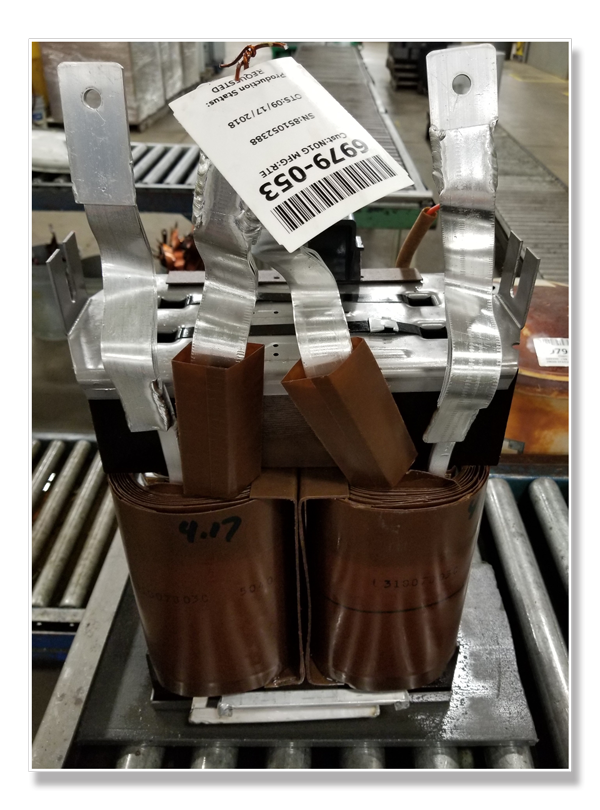

Upon arrival at NETS factory all nameplate data is catalogued and each piece of equipment is barcoded for electronic tracking through the facility.

2 DISASSEMBLY

After cataloging the transformer moves to disassembly. It is first given a preliminary evaluation of defects; Tank Corrosion, Broken Parts, Oil Leaks, Damaged Tank, Out of Date Design. The transformer is then opened, pumped, and completely disassembled. Each major component of the transformer transfers to a separate area in the factory to be processed.

3.2 CORE COIL

The Core/Coil undergoes several low voltage tests and a thorough quality assurance inspection. Parts conversion to update the coil to newer standards will also be performed. After passing inspection the Core/Coil is processed in NETS proprietary coil dry-out system that rejuvenates the coil and removes moisture, gasses, and particulates.

4 ASSEMBLY

Once all 4 major components are processed, all items re-unite in final assembly.

After assembly the transformer will undergo a series of inspections and low voltage testing to assure quality of the previous steps. After passing test it will be filled with hot oil under vacuum to remove any air pockets from the windings that might cause dielectric failure.

We hope you enjoyed our rebuild tour!

WHY CHOOSE US

POSITIVE ENVIRONMENTAL IMPACT

We annually remanufacture millions of pounds worth of metals/oil/plastics into transformers that meet new unit quality standards. Without our services these transformers would have been disposed of and new ones manufactured in their place.

Our warranty rate is lower than new manufacturers

Technology

NETS follows ANSI/IEEE testing and quality standards for each individual component of our transformers, and we monitor and follow new standard development. We also partner with transformer parts manufacturers to offer our customers the newest transformer products.